Conformal Coating Masking Tapes

Our conformal coating masking tapes provide the perfect protection for circuit board. This is because our dedicated tapes ensure areas remain free of the conformal coating at a low cost in terms of materials and labour.

Our conformal coating masking tapes provide the perfect protection for circuit board. This is because our dedicated tapes ensure areas remain free of the conformal coating at a low cost in terms of materials and labour.

These superior masking materials are used in our own global services and on conformal coating production lines around the world. Therefore, you can trust both the performance and reliability of the materials.

Call us on +44 1226 249019, email us at sales@schservices.com or click contact us to send us your requests.

Masking tapes available from SCH services

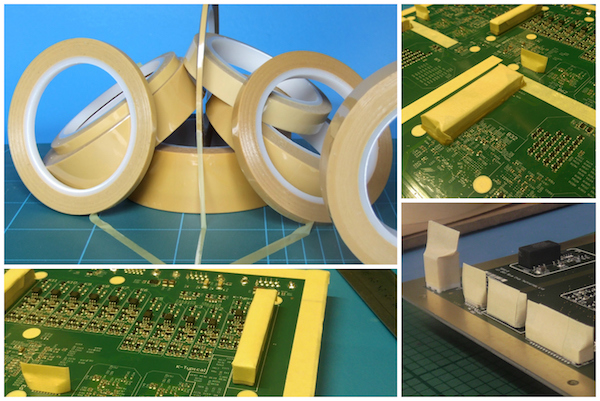

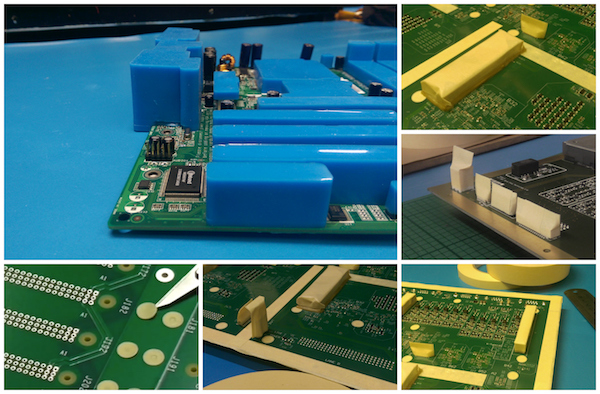

SCH offer two types of masking tape which compliment each other in the process:

- Crepe tape for masking components like connectors on the printed circuit board. The crepe tapes are available in sizes 3mm, 6mm, 9mm, 12mm, 25mm, 28mm and 50mm.

- Silicone free tape for masking grounding planes and flat sections such as edges of PCBs. This tape is available in sizes 3mm, 6mm & 12mm.

Call us on +44 1226 249019, email us at sales@schservices.com or click contact us to send us your requests.

Why use our conformal coating masking tapes?

Our conformal coating masking tapes provide the perfect protection for circuit board. This is because our tapes ensure areas remain free of the coating at low cost in terms of materials and labour.

SCH Technologies have trialed and tested a lot of different masking tapes over a long period of time. However, some adhesive tapes have problems being used for conformal coating processing

These problems include:

- Reacting in an adverse way with the conformal coatings themselves to produce de wetting effects

- Leaving adhesive residues when removed which need to be removed

- Allowing bleeding / leaking under the tape of the conformal coating during the application process

- Not staying sealed for long enough during processing

- Tearing when removed from the circuit board leaving residues of the tape behind

- Compatible with all types of conformal coatings including solvent based acrylic, silicone and polyurethane materials

Therefore, it was crucial for SCH to minimise these effects as much as possible in our coating services.

We wanted to provide the perfect protection to ensure areas remain free of the coating at a cost in terms of materials and labour that was sensible.

The conformal coating masking process

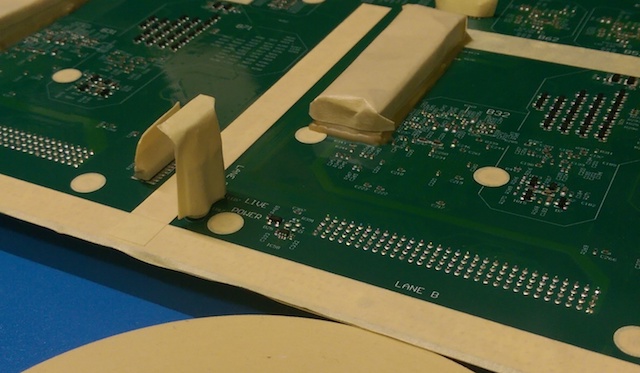

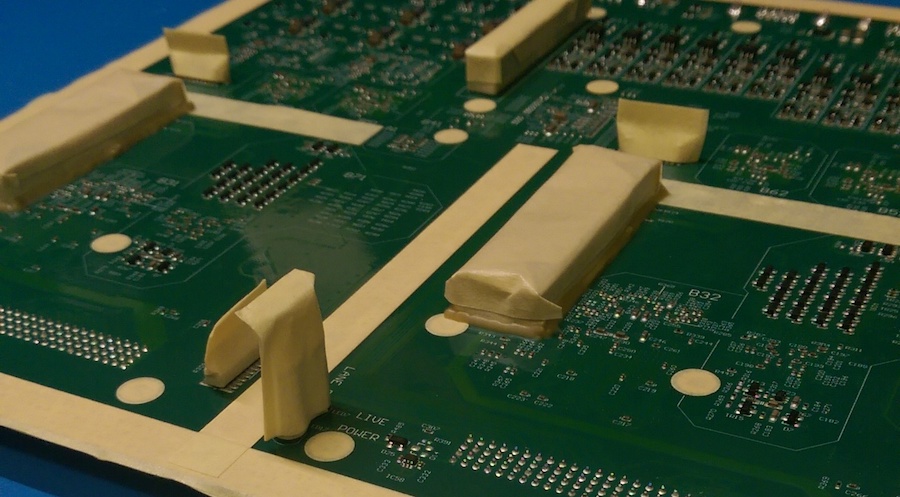

Many companies utilise conformal coating masking materials such as tapes, dots and masking boots to protect certain areas of their printed circuit boards from conformal coatings during application.

Many components and printed circuit board locations must remain uncoated. Therefore, the purpose of the conformal coating masking materials is to prevent migration of the conformal coatings into components and keep out areas.

SCH Technologies provide a range of tapes and masking boots that meet the highest standards required for liquid conformal coating processing whilst ensuring the products are price competitive.

Want to know more about conformal coating and the masking process?

Check out Nexus, an independent conformal coating resource, who provide detailed information on the masking process, and provide detailed examples for you to use in all areas of conformal coating.

Downloads

Links

- Materials for masking

- Custom boots for masking

- Tapes for masking

- Dots for masking

- Custom shapes for masking

- General masking FAQs

- Tape masking FAQs

- Custom boots FAQs

- Masking shapes FAQs

Contact us

If you would like to know more about coating services or other products and services offered and supported by SCH Technologies, please do not hesitate to contact us.

Call us on +44 1226 249019, email us at sales@schservices.com or click contact us to send us your requests.