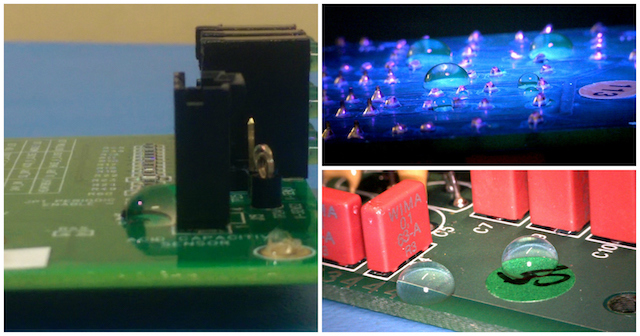

Opx Ultra-Thin Nano-Coating

OPX is a a very robust and abrasion resistant high performance PFPE blended with polysilane to form a highly hydrophobic nano-coating.

OPX is a a very robust and abrasion resistant high performance PFPE blended with polysilane to form a highly hydrophobic nano-coating.

OPX is a robust and long-lasting thin film that chemically bonds to almost any surface (silica, quartz, glass, metal and most plastics).

Why use nano-coatings to protect circuit boards?

Performance properties of OPX

The OPX fluorocarbon coating has excellent physical properties:

- Refractive Index 1.3

- Contact angle (water) >110°

- Contact angle (mineral oil) >70°

- Withstands 5000+ rubs with steel wool.

- Anti-scratching and anti-smudging properties makes OPX an ideal solution for coating: touch-panel displays, cell phones, LCD, optical filters/lenses and electronic boards

- Maintains contact angle after abrasion and exposure to IPA, acetone, others.

- Transparent film

- Protective coatings for electronic components – ALL of them. Protection for internal pcb, coatings for external case, sub-micron abrasion-resistant coatings for glass display

Talk to us about your requirements for fluoropolymer coatings.

Downloads

Why use nano-coatings to protect circuit boards?

Nano-coatings have very specialised properties for protecting circuit board assemblies.

They include:

- Being highly hydrophobic (water repellent)

- Having a high moisture barrier

- Being ultra-thin so no requirement to mask the circuit board

- Being highly oleophobic (oil repellent)

- Having a high chemical resistance

- Having a high lubricity

- Having high dielectric properties

- Providing high corrosion resistance

The fluoropolymers are extremely flexible coatings and becoming more prolifically used throughout engineering.

Contact us to find out more about nano-coatings for circuit board protection.

Downloads

- Technical Data Sheet OPX

- Technical Data Sheet LT-4

- Technical Data Sheet- LT-8

- Technical Data Sheet UVX

- MSDS TFP LT-4

- MSDS TFP LT-8

- MSDS TFP OPX

- MSDS TFP UVX

FAQs

- What is a nano-coating?

- Why are nano-coatings used?

- What sectors are nano-coatings being used?

- What products are actually coated in nano-coatings?

- Why select a nano-coating?

- How is a nano-coating applied?

- Can the nano-coating replace a traditional conformal coating?

- Where are nano-coatings being used?

- How much does the nano coating process cost?

- What are five key differences between a fluoropolymer coating (FC) and a conformal coating for protecting an electronic printed circuit board or assembly?

Nano-coating links

Links

Contact us

If you would like to know more about coating services or other products and services offered and supported by SCH Technologies, please do not hesitate to contact us.

Call us on +44 1226 249019, email us at sales@schservices.com or click Contact Us to send us your requests.