Conformal Coating Masking Dots

Our dedicated range of conformal coating masking dots are suitable for all production processes.

The reason why they work for conformal coating processing is simple. We carried out a large amount of research and trials to design a range of dots that was suitable for our own conformal coating services. Therefore, these masking dots are a tried and tested solution for anyone who wishes to use them in their own coating production.

To find out more about our conformal coating masking dots contact us now.

Why use our conformal coating masking dots?

Some masking dots and tapes have problems being used for conformal coating processing.

The issues include:

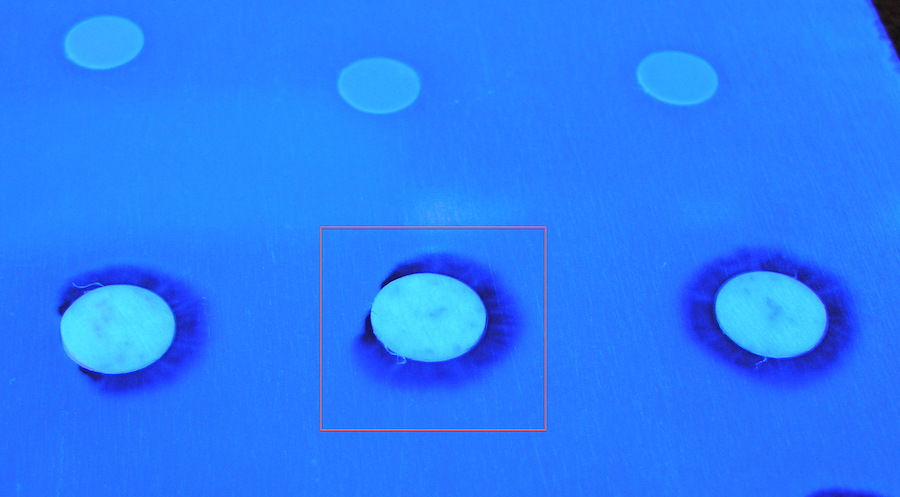

- They can cause de-wetting around the outside of the dot where the conformal coating pulls away from.

- Leaving residues when removed which need to be removed.

- Allow bleeding under the dot of the conformal coating during application.

- Tearing when removed making it difficult to process.

- Reacting in an adverse way with the conformal coating material.

Therefore, it is crucial to minimise these effects as much as possible and provide perfect protection to ensure areas remain free of the conformal coating .

To find out more about our conformal coating masking dots contact us now.

Conformal coating masking dots available

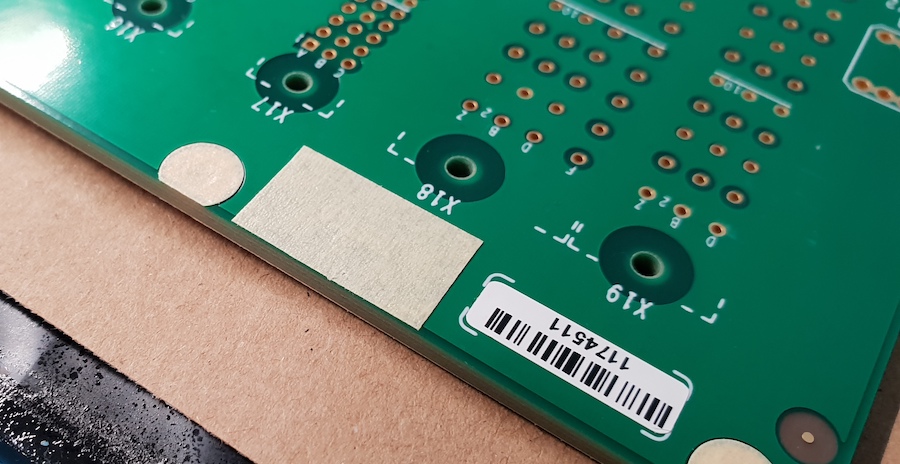

Our custom conformal coating masking dots are available in a range of sizes including 3mm, 4mm, 6mm, 8mm, 9mm and 10mm.

They are typically supplied on rolls for easy use although we can sell in smaller volume.

To find out more about our conformal coating masking dots contact us now.

The conformal coating masking process

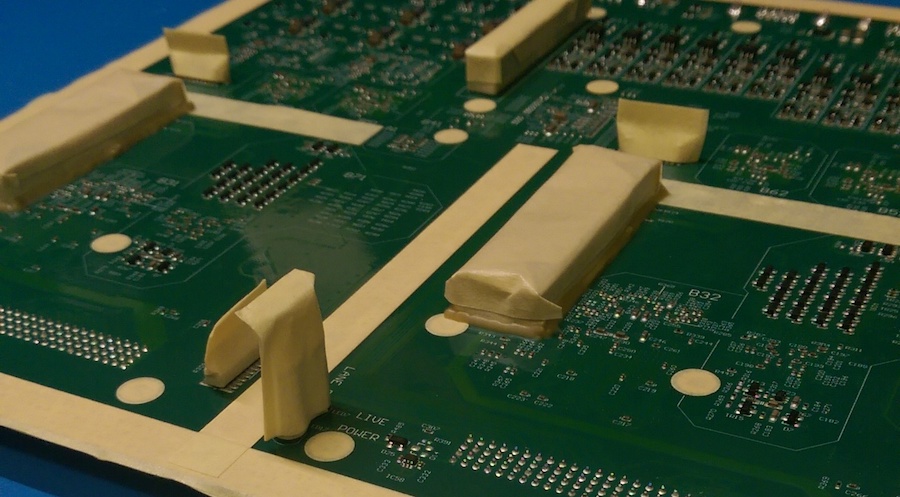

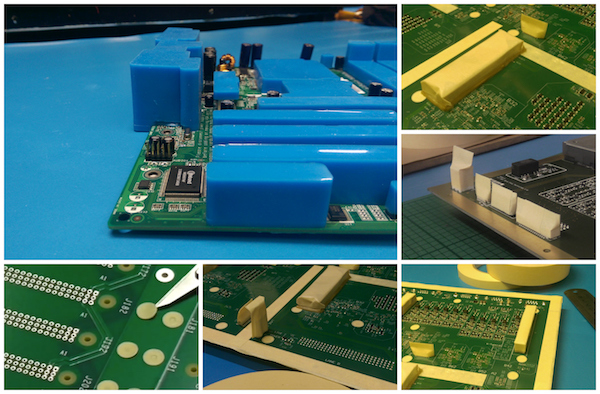

Many companies utilise conformal coating masking materials such as tapes, dots and masking boots to protect certain areas of their printed circuit boards from conformal coatings during application. This is because a lot of components on printed circuit board must remain uncoated.

The purpose of the conformal coating masking materials is to prevent migration of the conformal coatings into components and keep out areas.

SCH Technologies provide a range of tapes, dots and masking boots that meet the highest standards required for liquid conformal coating processing whilst ensuring the products are price competitive.

To find out more about our conformal coating masking dots contact us now.

Downloads

- Custom boots for conformal coating masking (PDF)

- Dots for conformal coating masking (PDF)

- Tapes for conformal coating masking (PDF)

Masking FAQs

- What would happen if I don’t mask a component or my circuit board correctly?

- What are the different methods for masking a circuit board before conformal coating is applied?

- Can I use any type of masking tape or dot in my conformal coating process?

- Are your conformal coating masking tapes and dots ESD safe?

- Why use a dot for conformal coating masking compared to any other dots available on the market?

- How cost-effective are the SCH conformal coating masking dots?

- Why does my masking dot make the conformal coating run away and create a “halo” around it?

Links

- Materials for conformal coating masking

- Custom boots for conformal coating masking

- Tapes for conformal coating masking

- Dots for conformal coating masking

- Custom tape shapes for conformal coating masking

- General masking FAQs for conformal coating

- Tapes FAQs for conformal coating processing

- Custom boot FAQs for conformal coating processes

- Custom masking shape FAQs for conformal coating processes

Contact us

If you would like to know more about coating services or other products and services offered and supported by SCH Technologies, please do not hesitate to contact us.

Call us on +44 1226 249019, email us at sales@schservices.com or click contact us to send us your requests.