DS101 Conformal Coating System

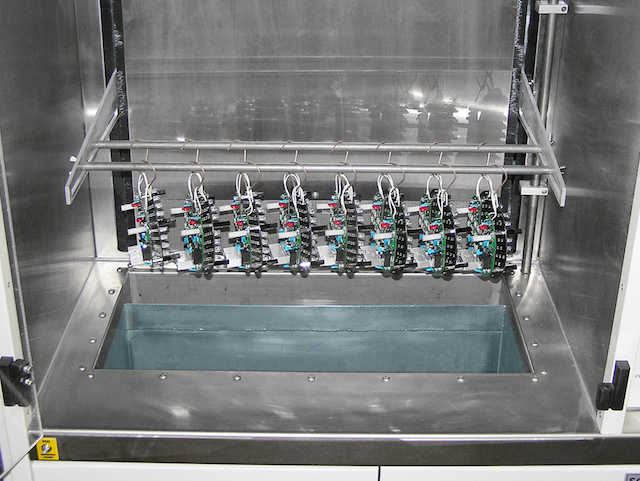

The DS101 Conformal coating dip system is a precision built, floor standing, conformal coating dip machine. It is designed for medium to high volume batch processing of printed circuit boards.

The system operates on compressed air only. Being entirely pneumatic the machine is safe to use with flammable materials. It also reduces the cost of expensive electronics required with explosive solvents.

The machine uses an air over oil pneumatic system for precision regulated speed control of the dip process. The automatic dip cycle process provides a smooth immersion and withdrawal rate which eliminates air entrapment and ensures an even film.

This allows a wide range of conformal coatings to be coated with repeatable high tolerance of conformal coating thickness to be achieved.

Standard features

- A pneumatically driven control & pump system operating from a single air inlet to meet the most stringent H&S needs

- Front-mounted control panel for easy operation

- Constant levelling re-circulating weir system

- Multiple horizontal support rods on dipping arm

- Compatible with solvent, silicone and water based coatings

- Fume extraction hood and extraction point for spigot to be fitted

- RoHS compliant system

Options

- Argon gas flow monitor and gas manifold

- Flow cup, viscosity tables and stop watch for material viscosity control

- Fixed steel rule to calibrate dipping speeds

- Teflon coated tank and panels

- Custom tank and dip system sizes

- Stainless steel weir catch tray

- Transparent doors fitted for minimal exposure to operators

- Automatic viscosity control and top up system

- Customised PCB jigging and carriers

Standard dip tank

- Stainless steel dip tank.

- Usable area is approximately:

- 600 mm long (left to right facing machine)

- 200 mm wide (front to back facing machine)

- 300 mm deep

- 50mm wide rear weir, 150mm deep for easy clean.

Structure

- The system is constructed of powder coated steel frame with solvent resistant stainless tank internal panels and tank.

- System is pneumatics only. No electronics are used.

Dimensions and weight

- Dimensions: ( approx) 1795 mm high x 950 mm wide x 590 mm deep.

- Dip tank: Stainless steel. Usable area is approximately 600 mm long x 200 mm wide x 300 mm deep with a 50mm wide rear weir, 150mm deep for easy clean.

- Range of dip speed: 0-150mm/min

- Tank Capacity: approx 40 litres.

- Weight: approx 155kg excluding coating

Facilities

- Clean, dry, compressed air at 80 psi

- 150mm extraction connection for spigot to be fitted

- 475 cfm for extraction with doors open, 30 cfm doors closed

Downloads

If you’re planning to install a piece of equipment, please check the exact specification of the brochure with us. All details shown in all brochures are subject to change between publication dates.

Setting up a conformal coating equipment line?

Consider our conformal coating equipment bundles.

Conformal coating dip coating FAQs

- How do you control the coating thickness in the dipping process and what is the tolerance of the coating thickness?

- How do I monitor the viscosity?

- What is the loading mechanism for the DS100 dip system?

- Can the DS100 utilise in line curing?

- Can I horizontally dip into the conformal coating using the DS101?

- Is the argon blanket an important option for the DS101?

- How often do you recommend a viscosity check on the conformal coating material in the DS101 tank?

- SCH have an option of automatic viscosity control and top up system for the DS101 dip coating system. Can you advise how this works?

- How is the height of the conformal coating material in the tank controlled on the DS101 dip coating system?

- Can the capacity of the DS101 tank be reduced?

Links for conformal coating equipment

Downloads

- Technical Specification Parylene lab coating system

- Technical Specification vertical Parylene coating system

- DS101 Dip coating system

- DS102 Dip coating system

- Inline and batch conformal coating dip system

- DC100 Drying cabinet

- CB100 spray booth

- Modus automated conformal coating inspection system

- UV200 UV Curing conveyor system

- UV Cure equipment

- UV inspection lamp

- IB100 Inspection booth

- IB101 Inspection booth

- Positector coating thickness measurement system

Links

Contact us

If you would like to know more about coating services or other products and services offered and supported by SCH Technologies, please do not hesitate to contact us.

Call us on +44 1226 249019, email us at sales@schservices.com or click Contact Us to send us your requests.