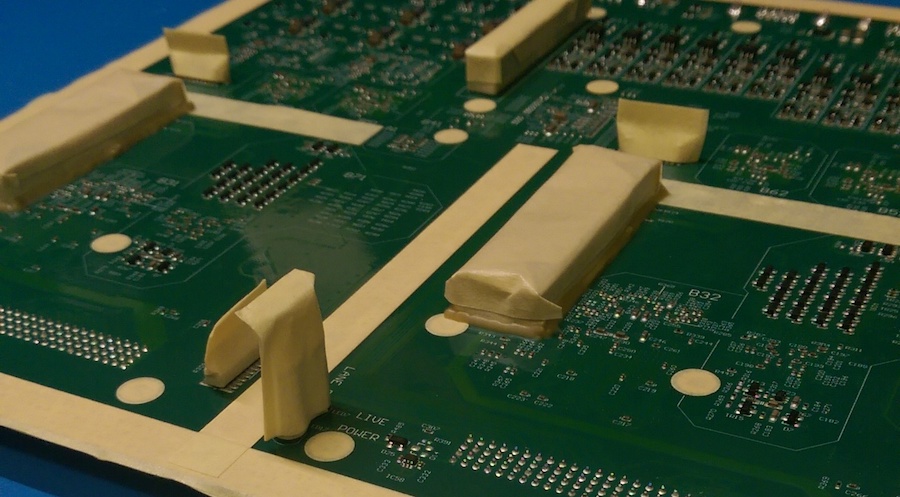

The use of various masking materials such as tapes, dots, and liquid latex can be an effective process in protecting components from ingress of conformal coating on a printed circuit board assembly.

However, the masking process can be difficult and time-consuming. This can increase the process costs significantly.

In fact, in many cases, the masking and de-masking processes can be >75% of the actual conformal coating process time and costs.

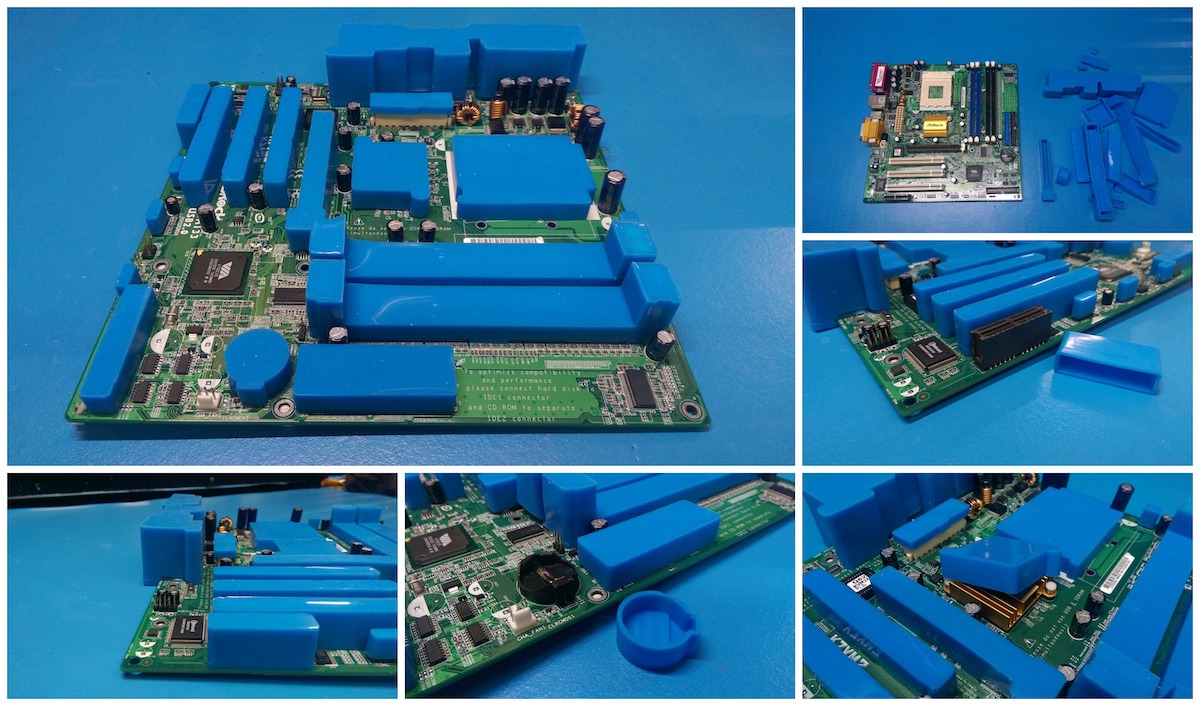

Using recyclable masking boots as an alternative to masking tapes, dots, and latex

Here are three good reasons to change to masking boots and save up to 80% of your costs compared to traditional methods like masking tape and dots:

- The masking time is reduced significantly. Masking boots can be 4-5 times quicker to use than masking tape.

- De-masking time is reduced significantly. Again it is much quicker to remove masking boots than tape.

- Masking boots don’t leak as easily as masking tape. So, there is less likely to be repaired.

These reasons mean you can save a lot of money very quickly when switching to masking boots.

Want to find out more about conformal coating masking boots?

Contact us to discuss your needs and let us explain how we can help you.

Contact us now.